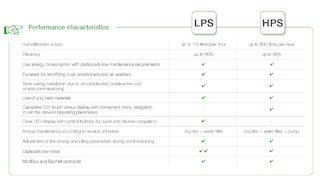

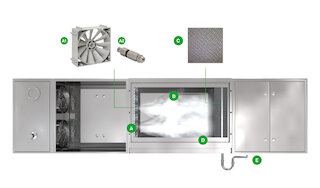

Our adiabatic humidification systems LPS and HPS (low- and high-pressure systems) have been developed for efficient use in comfort humidification. They provide for example in office complexes, hotels, shopping centres or clean rooms for the optimum relative humidity of the room air (comfort zone 40-60%) and are therefore an important element in company hygiene concepts and in the development of health-promoting measures.

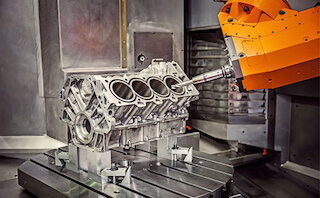

Also in process humidification, e.g. in production plants, in painting facilities or in the automotive and in the aviation industry, they reliably control the air humidity for optimum and stable production conditions.