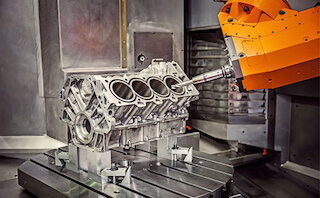

Wood is a natural raw material and, because of its hygroscopic properties, absorbs and emits moisture in accordance with its surroundings. When the air is too humid, it will tend to imbibe moisture, while releasing it if the relative humidity is low, which can cause deformations, tension or breakage to the material. So, the efficiency of the manufacturing process and the quality of the finished product heavily depend on constant, regulated air humidity in the working area.

If wood undergoes further processing, optimum air humidity ensures the high quality of adhesions, paint and laminates applied to the material. Fluctuations and low humidity levels impacts the drying time, and, for instance, can affect the strength of adhesives, causing the loosening or detachment of bonded elements.

Optimum humidification levels can also help maintaining a healthy working environment for employees processing wood. Air humidification binds the wood dust and prevents it to circulate in the ambient air, enabling occupants to work in a healthier space with lower dust pollution.

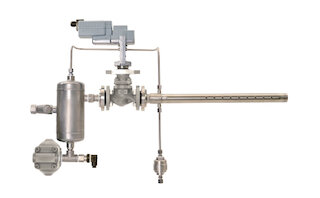

To reduce the warm indoor temperatures created by wood processing, the use of adiabatic humidification systems is recommended, as the units can achieve advanced, environmentally-friendly air cooling. Adiabatic systems help stabilise and maintain existing heat, achieving an optimum indoor climate.