We would like to keep you informed about interesting projects, new products and all the other exciting news from our company.

New! 3,5” Touch Control Remote

for our adiabatic systems

The new Touch Control Remote Display (3.5“ | 320 x 240 pixels) enables complete remote operation, control and configuration of HygroMatik’s adiabatic low- and high-pressure humidification systems from a distance.

Lounges Cleanroom Processes 2026

Visit HygroMatik in Karlsruhe

HygroMatik will be exhibiting for the first time at the Lounges trade fair, the event for cleanroom and process technology, and cordially invites you to visit us from 24 to 26 March 2026 at the Karlsruhe Exhibition Centre, Stand H1.7.

Air humidification presented at ISH 2025

Visit HygroMatik in Frankfurt

ISH 2025 - the world's leading trade fair for the HVAC industry - will welcome visitors from all over the world to Frankfurt am Main from 17 to 21 March 2025.

New steam manifold portfolio

for air humidification systems

Homogeneous steam distribution in ventilation systems and industrial steam systems plays a decisive role in hygiene, efficiency and controllability of humidity.

GET Nord 2024

Visit HygroMatik in Hamburg

Technology. Knowledge. Trends. Where the industry meets the future. Visit us at GET Nord from 21 - 23 November 2024 in Hamburg. We look forward to seeing you. Hall A1, stand 320.

MUTEC 2024

Visit HygroMatik in Leipzig

Visit us from November 7 - 8, 2024 in Leipzig at the international trade fair MUTEC for museum and exhibition technology, Hall 4, Stand D10.

HygroMatik PlannerApp HumiGuide

for planning air humidification

Download the "HumiGuide" from HygroMatik as an app on your smartphone from the app store, whether android or IOS.

New landing page

Air humidification in printing industry

Air humidification systems for a PLUS of PRECISION, EFFICIENCY and PRODUCTIVITY in the printing industry. Visit our new printing industry landing page.

Aquanale 2023

Visit HygroMatik in Cologne

We would like to invite you to Aquanale 2023 at our Hydrothermal Spa Forum joint stand.

The international trade fair for Sauna.Pool.Ambiente will take place in Cologne from 24 - 27 October.

New fixing nut for HygroMatik steam distributors.

Optimising quality always means paying particular attention to detail. Small, targeted improvements can have a major effect. For example, in HygroMatik steam distributors - the fixing nut has changed from a welded nut to a rivet nut.

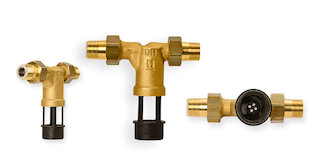

System separator type CA for direct connection to HygroMatik steam air humidifiers / steam generators.

According to DIN EN 1717, the drinking water network should be protected from contamination by water back-flow using appropriate system separators.

Actuator - optimised for HygroMatik steam air humidifiers.

Actuator with key function: The actuator is a central base element in the HygroMatik pressurised steam humidifier (DDS). It controls the regulating valve and so controls the volume of steam fed in.

Simply ingenious and rewarded several times: FlexLine is product of the year at the Plus X Award.

With the Plus X Award 2018, the new FlexLine from HygroMatik receives another very special seal of quality – in several categories even.

Change of ownership at HygroMatik

Carel Industries S.p.A. is the new owner of the HygroMatik GmbH effective since December 1st, 2018.

HeaterSteam – a compact steam generator for narrow recesses

The HeaterSlim has been fundamentally revised for you and is now even lighter and more compact in its dimensions. You get the handy solution, that fits into almost any niche, with a steam output of 6.6 or 10 kg/h.

MiniSteam E – the smart solution for direct humidification

All-round well thought out and in excellent quality that guarantees a long service life: The new MiniSteam E from HygroMatik is the safe and smart solution when it comes to direct room humidification.

SteamKit installation kits for a constant air humidity

HygroMatik SteamKits are now available to offer our customers a quick and uncomplicated solution for the individual equipment of their systems. The kits can be easily integrated into the systems and are available as electrode and heater types.

HygroMatik's new pressure steam systems DDS

The compact HygroMatik pressure steam systems DDS are connected to an existing steam network and thus make the pressure steam energy-efficiently usable for air humidification.

HygroMatik's new ventilation units VU

Our new ventilation units not only offer a simple and modern design but also feature a particularly smooth running and powerful cross-flow blower for optimum and homogeneous distribution of the humidified air in the room.

CAREL employee becomes a member of the HygroMatik team

We welcome Mr Felix Kreß from CAREL Germany to the HygroMatik sales team. Since January, he has enriched our team with his extensive knowledge of CAREL products and years of experience in the sale of air humidification systems.

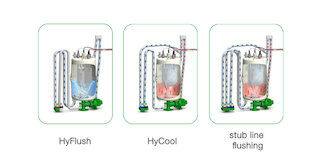

LPS and HPS: The new generation of atomising humidifiers

Our optimised adiabatic nozzle systems LPS and HPS humidify the air in air conditioning and ventilation systems hygienically and energy-efficiently.

Humidity study by RWTH Aachen University

At the Chair of Building and Indoor Climate Technology, E.ON Energy Research Centre, RWTH Aachen University, a comprehensive study in German was published at the end of February 2021 on the topic of "The influence of air humidity on people and their health.

New: Digital HygroMatik trade fair stand

At our new digital HygroMatik trade fair stand, we will provide you with information on the subject of HEALTHY INDOOR AIR and present a selection of our product range for the generation of optimum indoor air humidity in many areas of application.

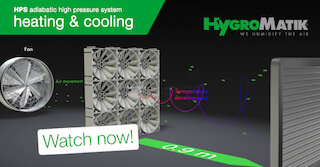

Adibatic Humidification for heating and cooling!

See for yourself, the operating principle video of the atomising humidifier from HygroMatik.

The adiabatic high pressure system (HPS) is highly efficient with an absorption distance below 0,9 m.

HygroMatik digital spa showroom for steam generators

Discover the digital HygroMatik spa showroom.

HygroMatik SteamKits - New sizes, more choice!

Manufacturers of climate control cabinets, ovens and cleanroom workbenches have relied on the proven quality of our steam humidifier installation kits for years.

FlexLine options - protection and safety at its best!

New! HyTherm for effizient air humidification.

The thermo collar for all stainless steel cylinders of the FlexLine Plus/Process heater type steam humidifiers.

Use of softening systems with HygroMatik heater type steam humidifiers

Drinking water contains minerals in more or less high concentrations, which usually precipitate when heated. In order to keep the cleaning effort of the steam humidifier as low as possible, there are two possibilities for water treatment.

Change in the management of HygroMatik

Mr Oberhaus, currently also Managing Director of Klingenburg GmbH, will in future manage both companies with the aim of developing the best possible synergies within the technical, sales and production structures of the group.

HygroMatik goes ISH 2023

Visit us in Frankfurt

The ISH has taken on board the need for information on the subject of healthy indoor air and will inform the trade public from 13 – 17 March 2023 about all aspects of ventilation and air quality.