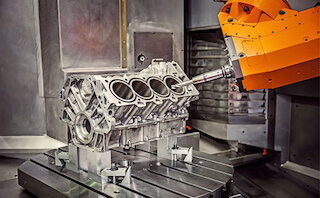

A stable and controlled room climate is indispensable for many production processes. Fluctuations in air humidity and especially excessively dry air have a massive influence on the raw materials used, on their processing capabilities and thus ultimately also on the quality of the end products.

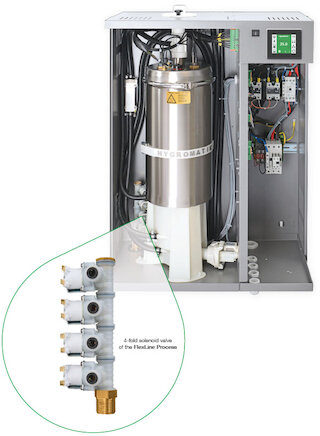

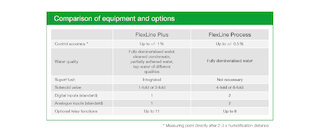

HygroMatik FlexLine Plus and Process heater steam humidifiers have been developed especially for the use in precision and process humidification, in sensitive areas of industrial production as well as for the stabilisation of the relative air humidity in laboratories and research facilities.